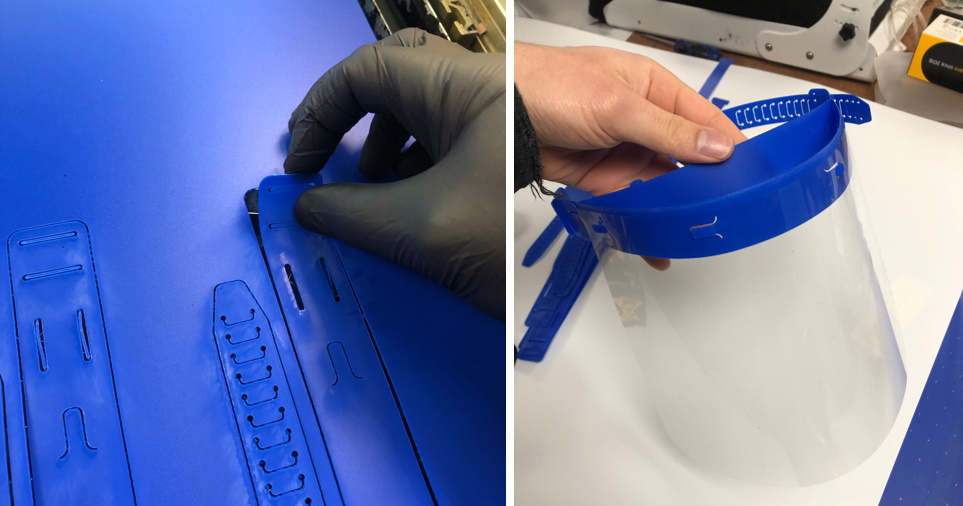

“We are able to cut visors at a rate of around one every 2 minutes”

Nathan Ruttley

We are living in extraordinary times, and engineers are doing remarkable work to come up with innovative solutions to help our key workers. Graduated UKESF Scholar Nathan Ruttley (University of Southampton) is helping to protect NHS staff during the COVID-19 crisis by using his company’s laser cutter to produce headbands for visors. Here Nathan tells us about what he has been up to since graduation and how he got involved in fighting the spread of COVID-19.

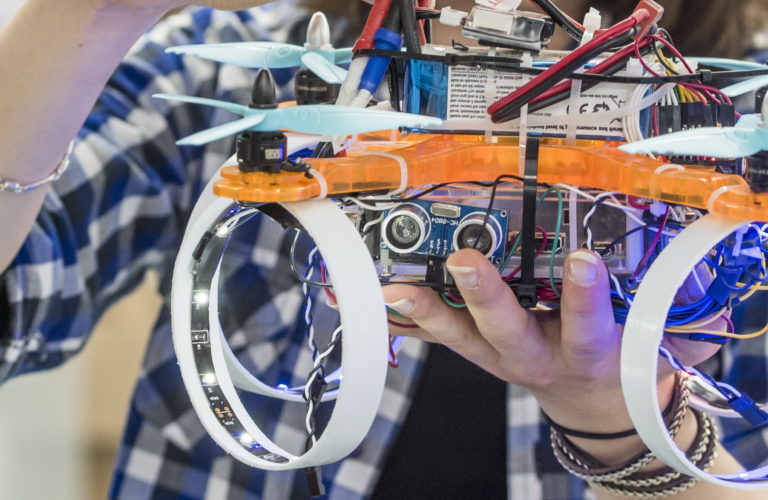

After graduating I worked for RPD International up until mid-2019. I spent some time in China delivering a project for them (Radbot) for which I won an Electronics Weekly BrightSparks Award. After leaving RPD I started a boutique consultancy company, Embedism, with an old colleague of mine; our pitch is that we offer affordable prototyping and electronics+firmware development for start-ups. We operate on extremely low overheads which means we can deliver great value to clients and turn projects around quickly – meaning we get to work on lots of different types of projects (and hence increase our value to our clients!). We have a fully kitted-out workshop in Kingston with full soldering setup including reflow, hot air and micro solder, 3D printers, a large bed laser cutter, a good array of electronic test equipment and other prototyping bits and bobs.

Regarding the visors, a company called Kitronik who supply education electronic and DT resources came up with a laser-cuttable design, so we sourced materials from B2B suppliers (since we are a proper LTD company we were able to get great rates and fast delivery). We were inspired by the efforts of many hobbyist 3D printing enthusiasts so though we should put our laser cutter to use. We are able to cut visors at a rate of around one every 2 minutes and have made over 1,700 headbands so far. These headbands get distributed to volunteers for final assembly and distribution to their local NHS facilities.

© Nathan Ruttley

In the short term we are working on building our client base and reputation. In the long term we might think about expanding (so long as it fits with our ethos of low overheads) but primarily we want to develop our own range of electronic products that we can manufacture and sell.

Find out more about Nathan’s company Embedism here, and watch a short video of his laser cutter in action here.